Turbo Modular Fragmented Ice Machines

The Modular Fragmented Ice System is a new approach to producing fragmented ice that Turbo Products has engineered. The system features increased flexibility for customers while being able to retain the key operating and efficiency advantages that have always been the trademark of the Vogt Turbo fragmented technology.

MCLA: Modular C-Line Ammonia

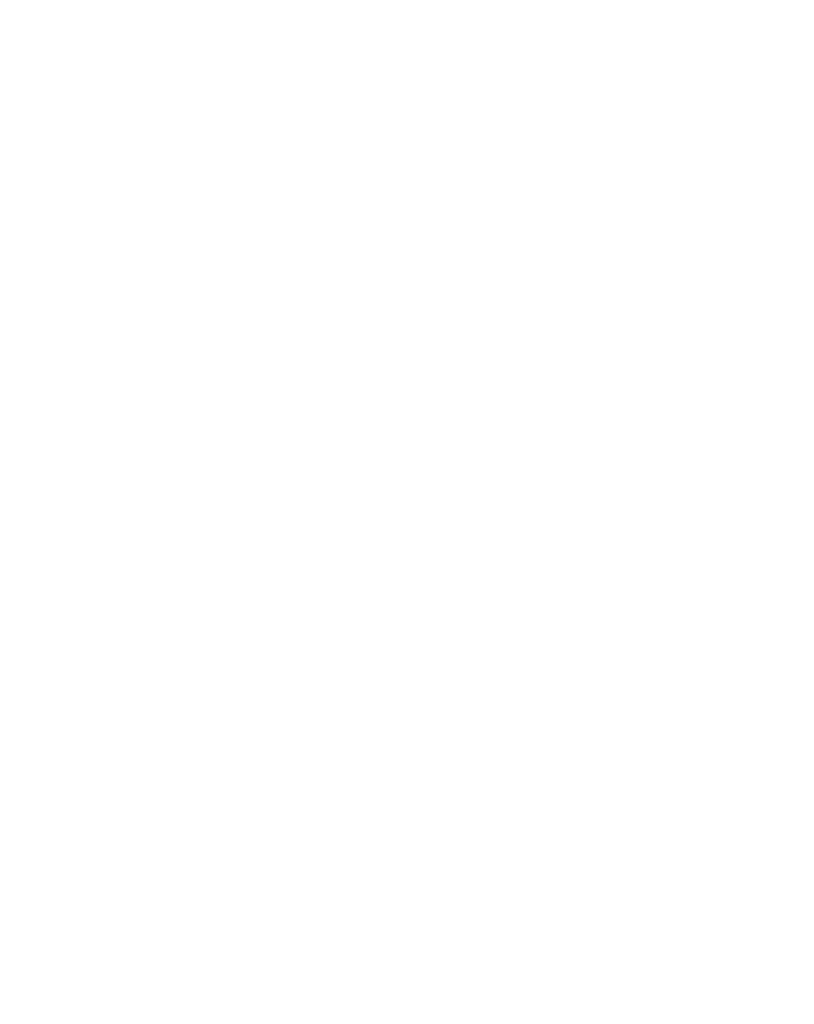

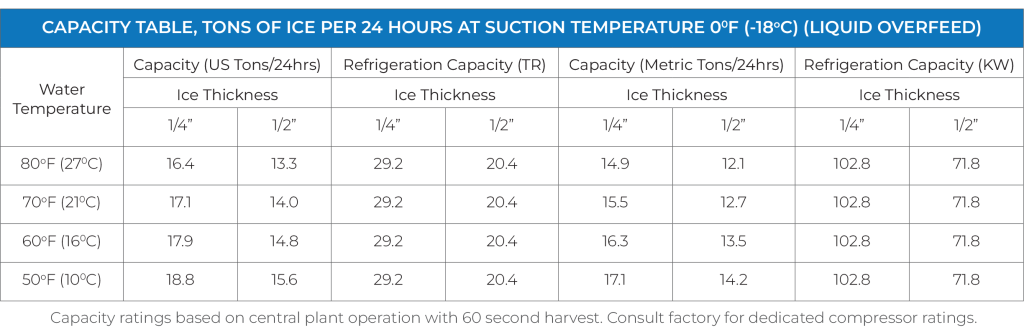

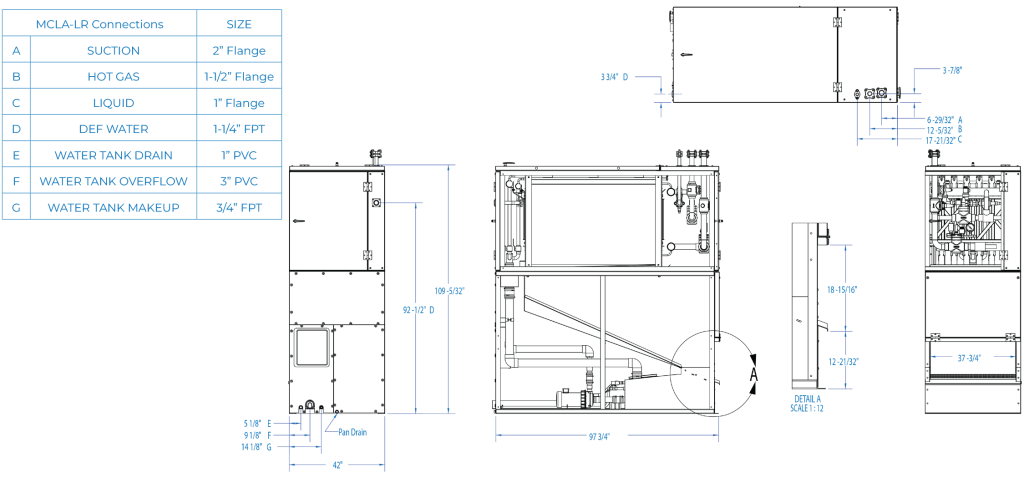

The Turbo Products MCLA (Modular C line Ammonia) uses a water defrost, water pre-chill and hot gas for the defrost harvest cycle. Individual modules produce 13 to 19 tons per day of 1/4” to 1/2” fragmented ice which is dry to touch and immediately ready to package or use. These modules can be assembled in a programmed sequenced array with a master panel to produce ice over 250 tons per day.

MCLA Standard Features:

- Ammonia Operation (Liquid Recirculated)

- Stainless Steel Front and Rear Panels

- Voltage – 230V or 460V, 3PH, 60Hz Power

- Voltage – 120V, 1PH, 60Hz Controls

- Allen Bradley Micrologix PLC

- Stainless Steel Evaporator Piping

- Stainless Steel Upper and Lower Frame

MCLA Options:

- Voltage – 400V, 3PH, 50Hz Power

- Voltage – 575V, 3PH, 60Hz Power

- End Panel Kit

- AB Ethernet Interface Module

- Split Crating for Container/LTL Loading

- Canadian Registration Number (CRN)

- Export crating (ISPM-15 Rated)

- Automation Direct PLC (Module only)

- R/S Control Valves

- Base Frames / Headers for Skidding up to 6 Modules

- Master Panels for Control of up to 18 Modules

- Hot Gas/Liquid Strainer/Defrost Pressure Regulator Kit

Principles of Operation

Operating Conditions

The ice machine shall not be subjected to an atmospheric temperature lower than 50oF (10oC) nor higher than 90oF (32oC) without effect on performance. Water for condensing or ice making purposes shall be non-corrosive. The water shall be at a constant pressure no less than 30lb at the ice machine location. The condition of the water to make satisfactory ice shall be the responsibility of the purchaser.

CONTACT A SALES REPRESENTATIVE

phone: (800) 325-3667

email: [email protected]

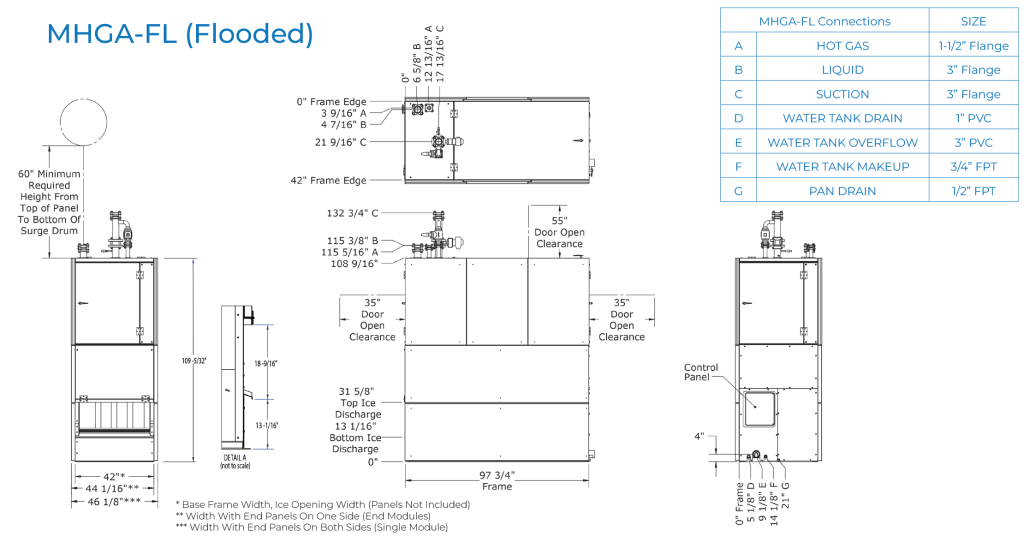

MGHA: Modular Hot Gas Ammonia

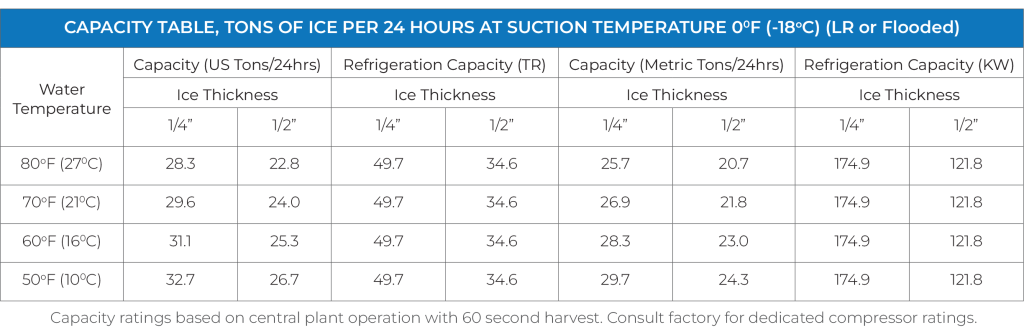

The Turbo Products MHGA (Modular Hot Gas Ammonia) are microprocessor controlled ice modules that can be combined to operate alone or as part of a sequenced modular ice making array for 25 tons to over 300 tons of ice per day. This ice discharges in 1/4” to 1/2” plate fragmented ice which is moist on the surface but does not readily clump in storage. A single master control panel provides network accessibility for precisely monitoring and controlling ice making operations.

MCLA Standard Features:

- Ammonia Operation (Liquid Recirculated or Flooded)

- Stainless Steel Front and Rear Panels

- Voltage – 230V or 460V, 3PH, 60Hz Power

- Voltage – 120V, 1PH, 60Hz Controls

- Allen Bradley Micrologix PLC

- Stainless Steel Evaporator Piping

- Stainless Steel Upper and Lower Frame

MCLA Options:

- Voltage – 400V, 3PH, 50Hz Power

- Voltage – 575V, 3PH, 60Hz Power

- End Panel Kit

- AB Ethernet Interface Module

- Split Crating for Container/LTL Loading

- Canadian Registration Number (CRN)

- Export crating (ISPM-15 Rated)

- Automation Direct PLC (Module only)

- R/S Control Valves

- Base Frames / Headers for Skidding up to 6 Modules

- Master Panels for Control of up to 18 Modules

- Hot Gas/Liquid Strainer/Defrost Pressure Regulator Kit

Operating Conditions

The ice machine shall not be subjected to an atmospheric temperature lower than 50oF (10oC) nor higher than 90oF (32oC) without effect on performance. Water for condensing or ice making purposes shall be non-corrosive. The water shall be at a constant pressure no less than 30lb at the ice machine location. The condition of the water to make satisfactory ice shall be the responsibility of the purchaser.

CONTACT A SALES REPRESENTATIVE

phone: (800) 325-3667

email: [email protected]