Stretch Wrapping Machines

Automatic ICE™ Systems partners with Lantech to fully customize and integrate their stretch wrapping machines to work seamlessly within our systems, delivering the best and most innovative product solutions.

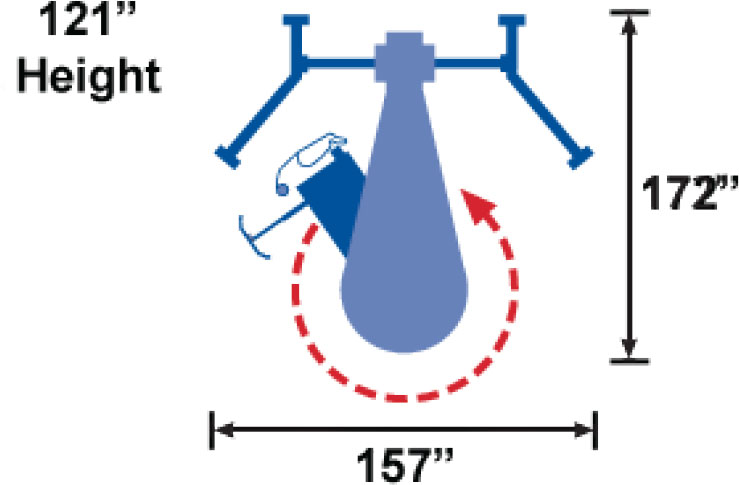

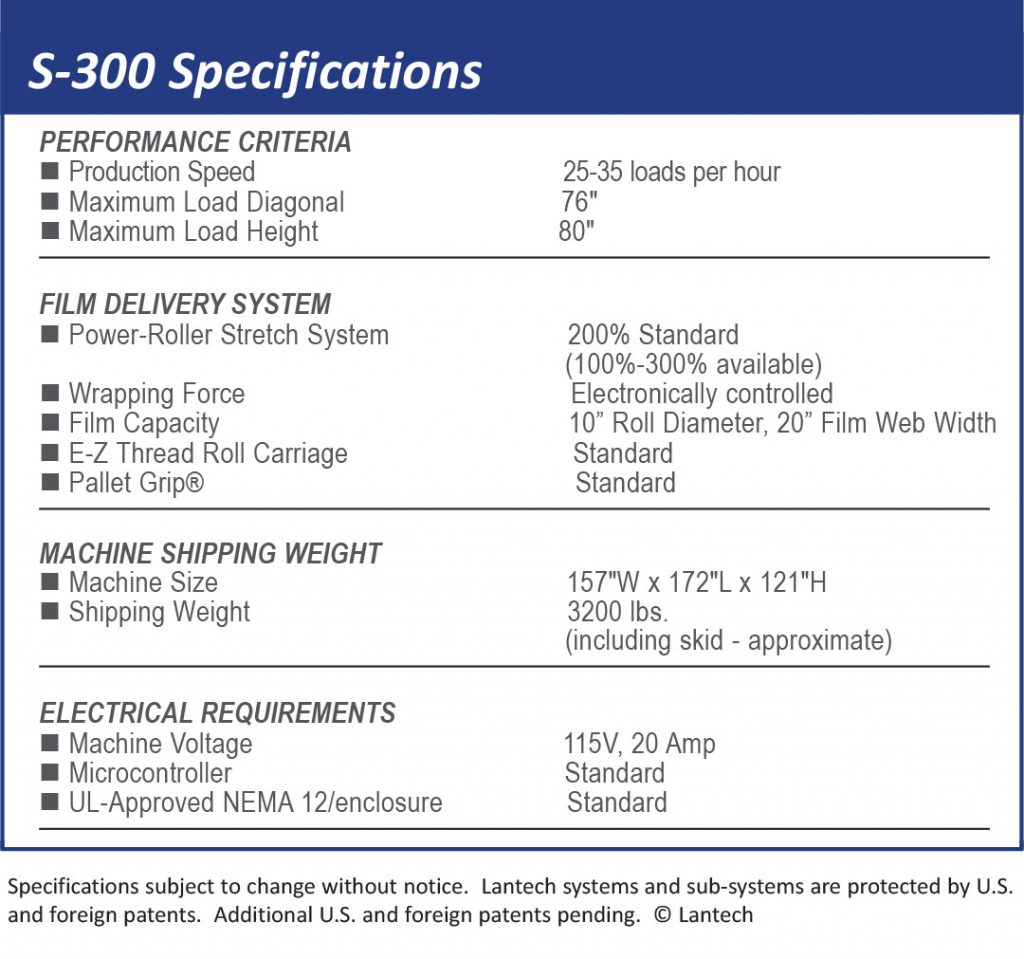

Lantech S-300 Semi-Automatic Straddle Stretch Wrapping System

Ideal for Very Light, Very Heavy or Very Unstable Loads.

Boost your machine’s performance with these patented features:

– Auto Film Cut-off ™ Save 30 seconds of labor per load!

– Automatically punctures film so it cuts off at the corner of the load

Features:

• Load Doesn’t Rotate

• No Weight Limitations

• Precise Application of Wrap Force

• Locks Load to Pallet with Film Cable

• No Scheduled Preventative Maintenance

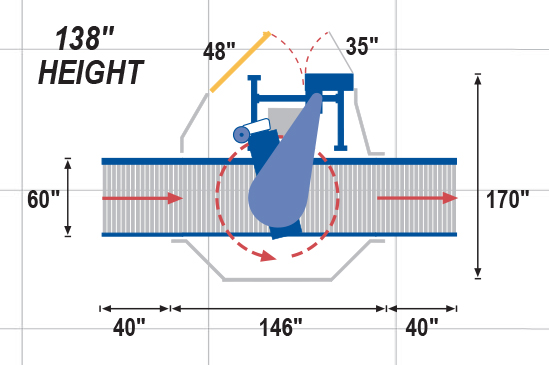

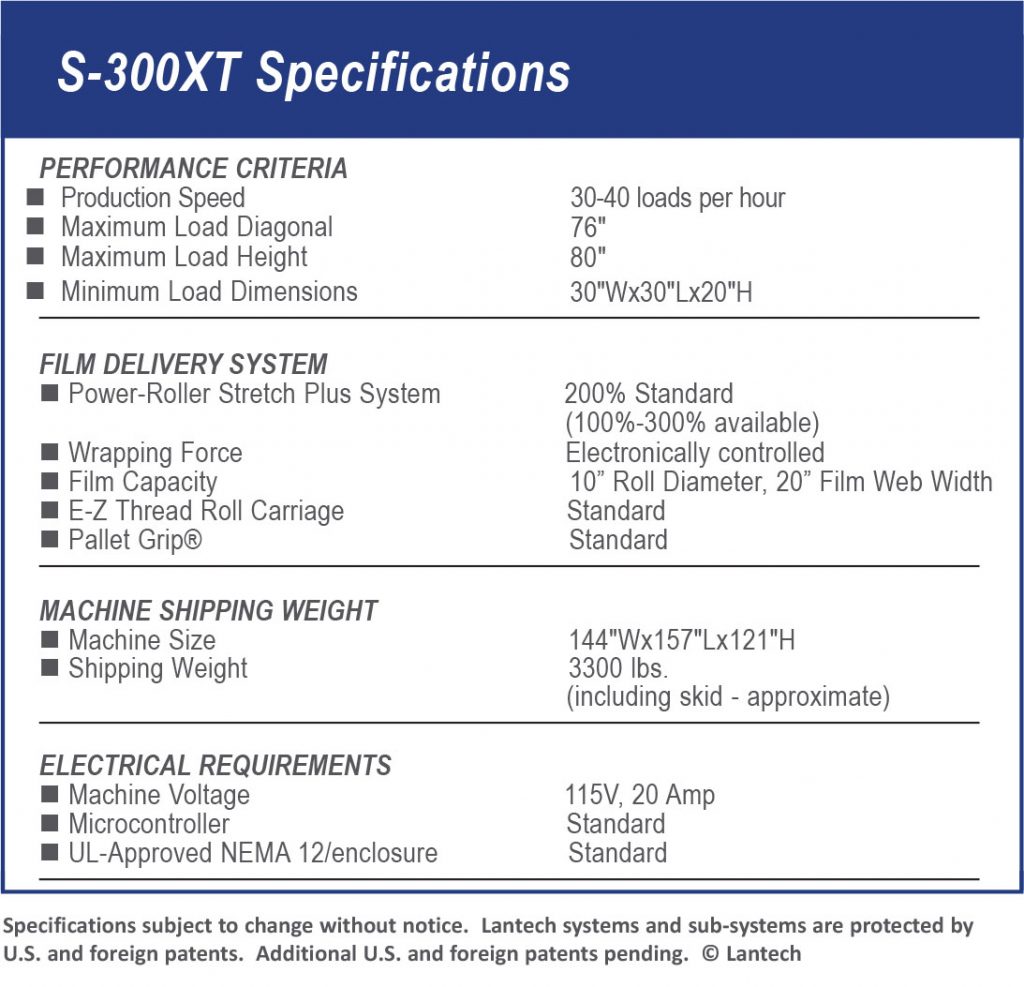

S-300XT Simple Automation™ Stretch Wrapping System

Work Smarter … Keep Your Driver on the Forklift!

Boost your machine’s performance with these patented features:

– Click-n-Go™ Stretch Wrapping Loads at the Touch of a Button!

– Enhances portability by eliminating requirement to install a ceiling-mounted lanyard

– Each unit can handle up to 3 machines

– Click-n-Go remote meets the latest safety requirements outlined by the National Electrical Code

– Using infrared technology and two-step activation process, the Click-n-Go is immune to accidental activation from stray radio frequency

Features:

• Patented XT Cut and Clamp® Automatically Captures the Stretch Film and Cuts it at the End of the Wrap Cycle

• Save 2 Minutes of Forklift Driver Labor per Load

• No Scheduled Preventative Maintenance

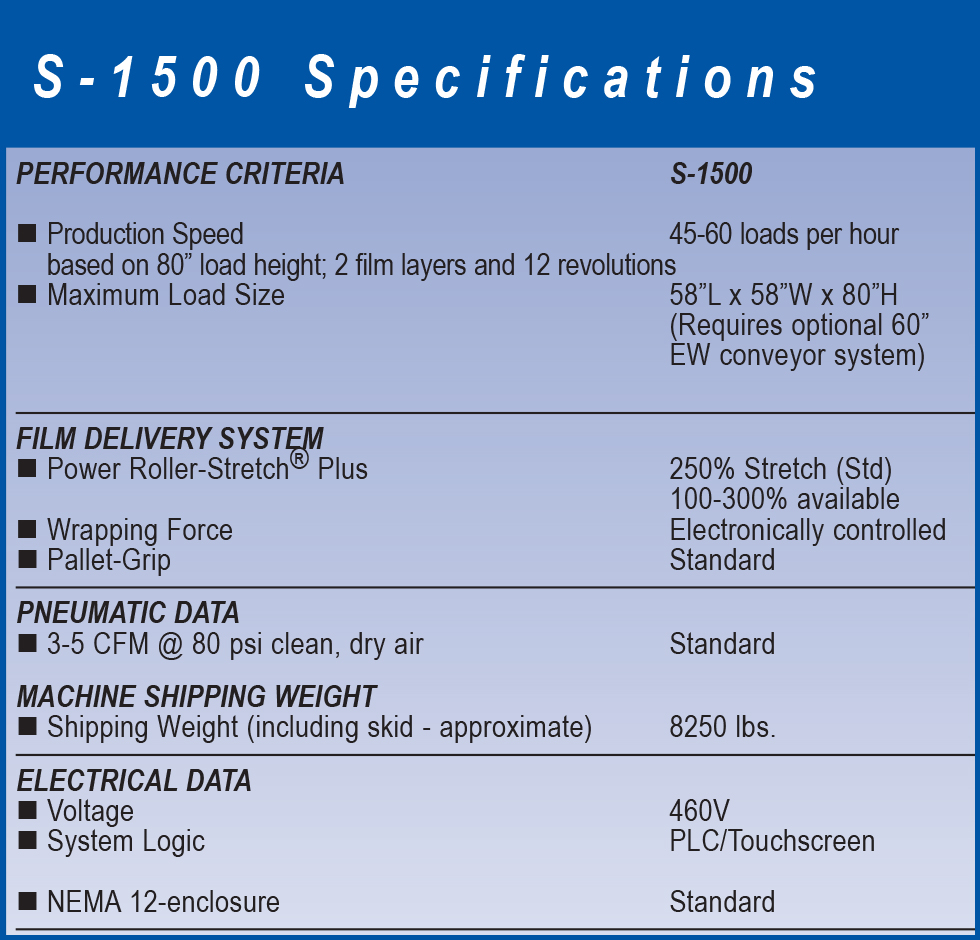

S Automatic S-1500 Automatic Straddle Stretch Wrapping System

Features:

• 45-60 loads per hour

• Reduce labor and increase throughput with automated load indexing, attaching, cutting and wiping film

• Automation with minimum space requirements

• Flexibility allows in-line, end-of-line, or freestanding configuration where load accumulation is beneficial