Robotic Palletizing Systems

JMC Ice Robotic Palletizing

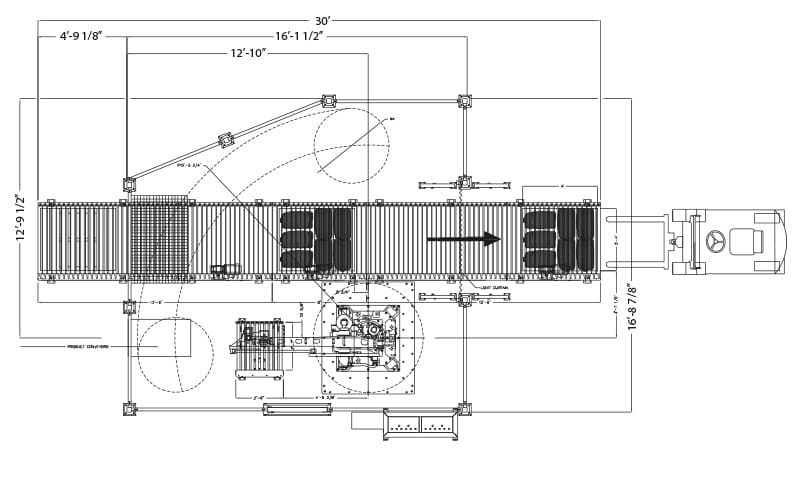

Typical automatic, single-infeed, single-output system. Dimensions are approximate and for reference purposes only. Consult the factory for full engineering details and for power and air requirements.

Partnered with FANUC Robotics, the global leader in robotic automation, JMC Packaging Equipment now offers the packaged ice industry leading-edge technology with complete robotic-based palletizing solutions. All our systems are custom-designed for each ice plant and are offered on a turnkey basis to meet or exceed customer expectations for performance and reliability.

With more than 400 automatic master ice balers in operation and with over 25 years of experience, JMC Packaging Equipment has developed a reputation within the packaged ice industry for outstanding quality, reliability, and after-sales service.

ADVANTAGES OF OUR ROBOTIC BASED PALLETIZING SOLUTION

High reliability – Servo motor-driven operation

Maximum uptime – over 56,000 hours documented between failures

Low operating costs – Scheduled maintenance requires simply a grease change

Consistent pallets – Highly precise movement

Flexibility – Can handle multiple infeeds and outfeeds

Non-redundant – Easily adaptable to fit changing needs

CONTACT A SALES REPRESENTATIVE

phone: (800) 325-3667

email: [email protected]

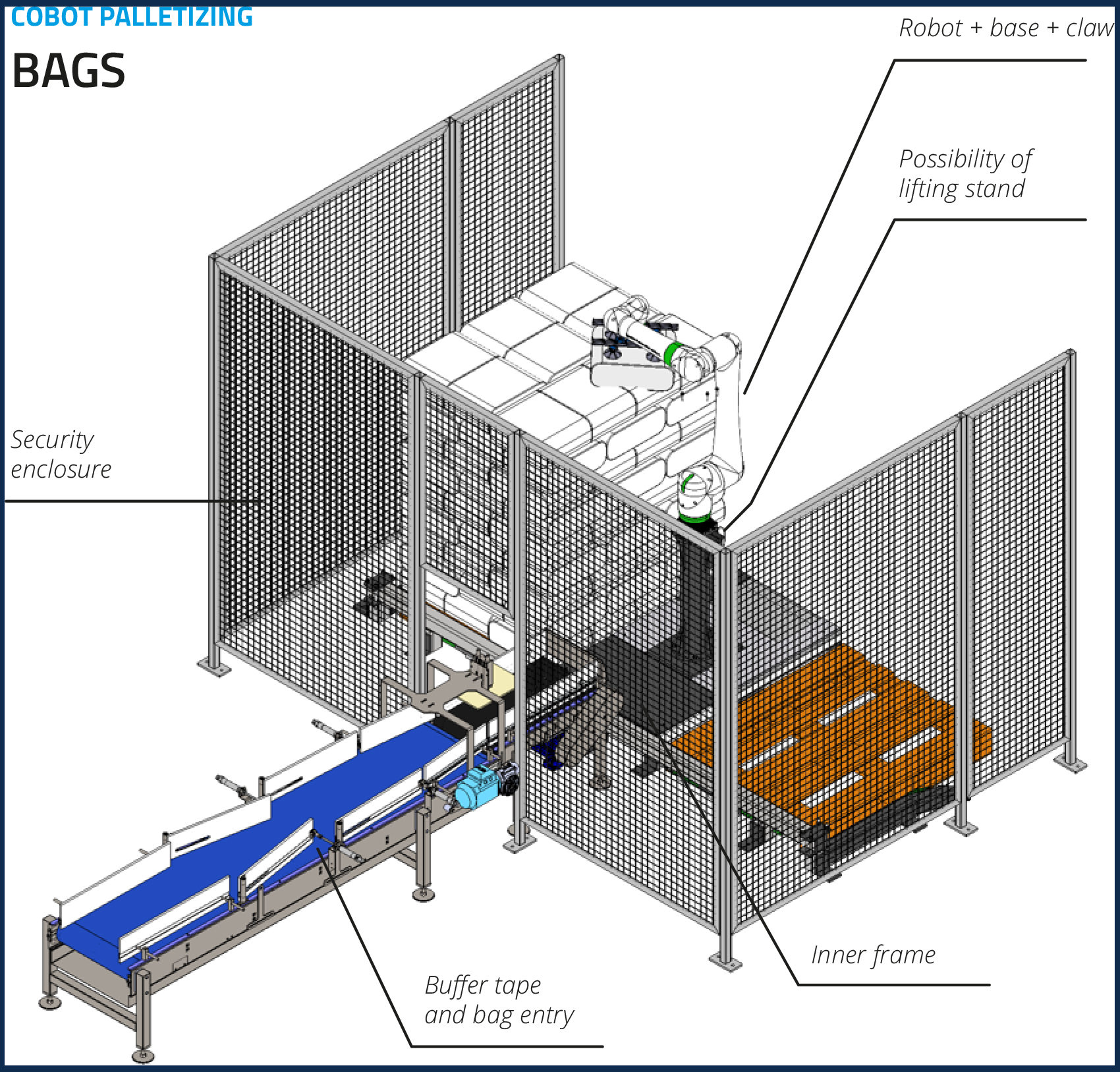

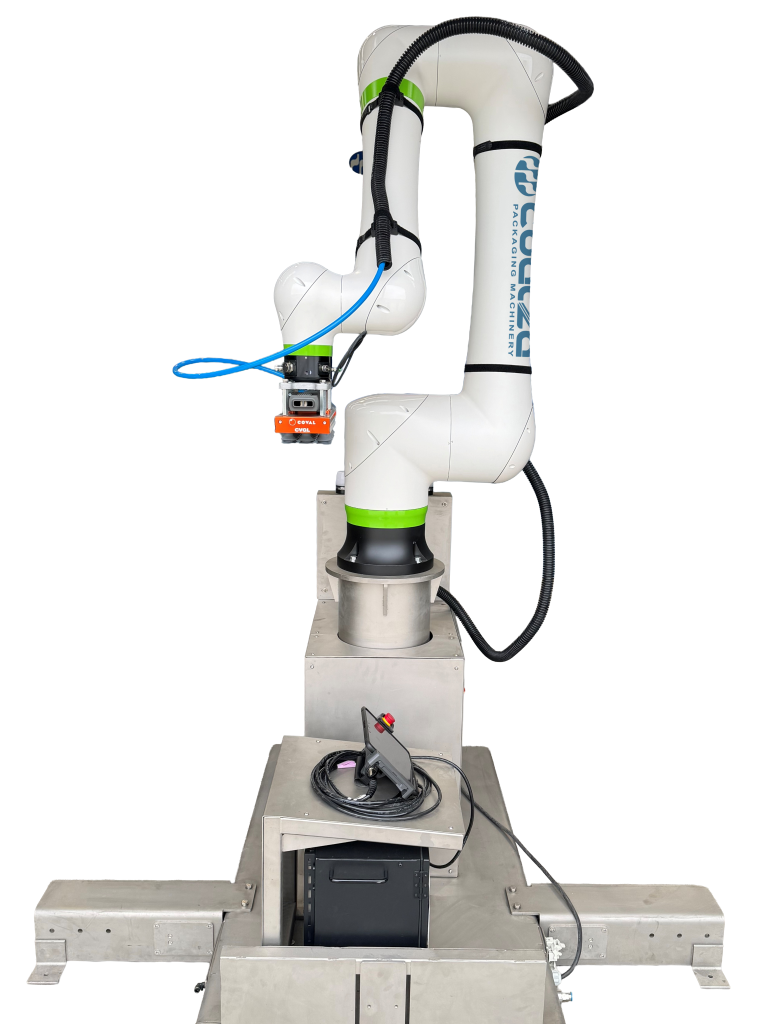

Coalza CoBot Palletizer

Robotic Palletizing

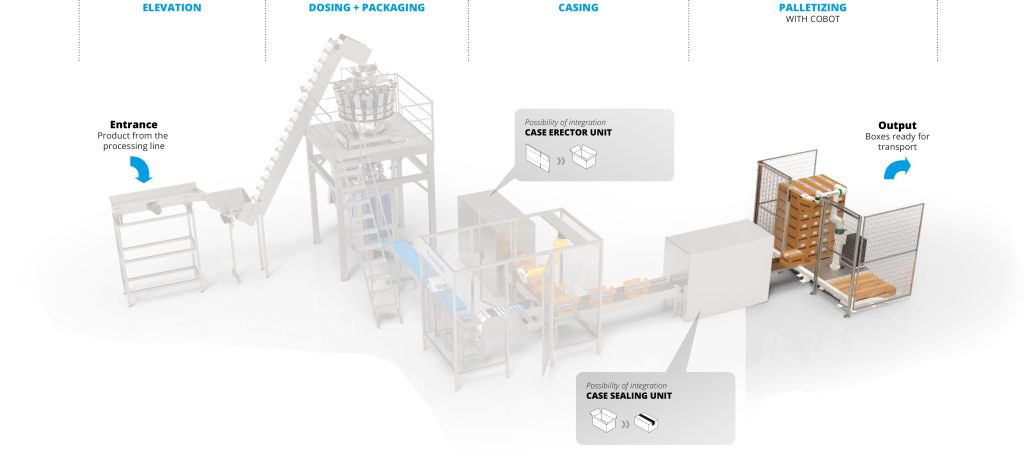

Specially designed for palletizing bags and boxes of different formats. It is the best solution for automating end-of-line processes, increasing productivity and efficiency in the plant.

Fully Automated

From incorporating the product for packaging to loading the boxes for transportation.

Versatility and adaptability to the space available in your packaging plant

Wide range of possibilities by combining dimensions of bags and boxes

STANDARD FEATURES

| Model | PCS – 10 | PCS – 20 | PCS – 25 |

| Max. number of cycles (speed) | |||

| Collaborative mode | 6-8 cycles/min (1m/s) | 6-8 cycles/min (1m/s) | 6-8 cycles/min (1m/s) |

| Non-collaborative mode | 10-12 cycles/min (2 m/s) | No option | 10-12 cycles/min (2 m/s) |

| Pallet type | European and American (option of other sizes) | European and American (option of other sizes) | European and American (option of other sizes) |

| Max. pallet height | w/ fixed base 5.4 ft | 5.4 ft | 6.2 ft |

| w/ lifting stand 8.2 ft | 8.2 ft | 8.2 ft | |

| Max. load capacity at wrist | 22 lbs | 44 lbs | 55 lbs |

| Machine finishing (optional) | Stainless steel or painted steel | Stainless steel or painted steel | Stainless steel or painted steel |

CONTACT A SALES REPRESENTATIVE

phone: (800) 325-3667

email: [email protected]