Fully Automatic Packaging

Automatic ICE™ Systems partners with industry leaders Coalza and Hamer to fully customize and integrate their fully automatic packaging equipment to work seamlessly within our systems. Delivering the best and most innovative product solutions.

Coalza RSC300-DH Packaging Machinery

The Coalza RSC series DH units are designed to be the highest-speed packaging machines in the Coalza lineup. This vertical form, film, and seal packaging machine has been revamped to optimize operational efficiency, reduce packaging disruptions, and minimize preventative maintenance costs for packaged ice producers.

- Designed for High-speed packaging

- Up to 55, 7lb-bags per minute

- Product range: 2kg- 5kgs (5lb-10lb bags). Cups for the volumetric system will be customized according to customer’s weights requirements

- Proven ice packaging reliability with less operational disruptions

- Long service life with minimal annual PM requirements

- No wasted packaging film

MODEL: RSC300-DH

| Dimensions (WxLxH): | 1424mm x 2070mm x 2797mm (56” x 81” x 110”) |

| Power: | 460V., 3P., 60Hz |

| Bags Per Minute*: | 5 lb/ 7 lb: up to 50-55 bpm 10 lb: up to 45-50 bpm |

| Max Bag Width**: | 11.8” (300 mm) |

*Depends on the product and the film. **Empty bags.

Coalza RS400-DH Packaging Machinery

The industry-proven Coalza RS series DH packaging machines are specially designed for food-safe ice packaging operations. This vertical form, film, and seal packaging machine has been redesigned to better accommodate the needs of North American packaged ice producers. More operational uptime, fewer packaging disruptions, and lower PM costs make this proven packaging platform a better solution.

- Proven ice packaging reliability with less operational disruptions

- Very low annual parts consumption, typically under $1500/ year

- Long service life with minimal annual PM requirements

- No wasted packaging film

MODEL: RS400-DH

| Dimensions (WxLxH): | 1680mm x 2070mm x 3047mm (67” x 82” x 120”) |

| Power: | 460V., 3P., 60Hz |

| Bags Per Minute*: | 32 (faster speeds available with other models) |

| Max Bag Width**: | 17.7” (450mm) |

*Depends on the product and the film. **Empty bags.

Coalza RS300-DH Packaging Machinery

The industry-proven Coalza RS series DH packaging machines are specially designed for food-safe ice packaging operations. This vertical form, film, and seal packaging machine has been redesigned to better accommodate the needs of North American packaged ice producers. More operational uptime, fewer packaging disruptions, and lower PM costs make this proven packaging platform a better solution.

- Proven ice packaging reliability with less operational disruptions

- Very low annual parts consumption, typically under $1500/ year

- Long service life with minimal annual PM requirements

- No wasted packaging film

MODEL: RS300-DH

| Dimensions (WxLxH): | 1222mm x 2017mm x 2554mm (49” x 80” x 101”) |

| Power: | 460V., 3P., 60Hz |

| Bags Per Minute*: | 32 (faster speeds available with other models) |

| Max Bag Width**: | 11.8” (300mm) |

*Depends on the product and the film. **Empty bags.

Hamer Model 540E Form Fill & Seal (FFS) Packaged Ice Machine

CONTACT A SALES REPRESENTATIVE

phone: (800) 325-3667

email: [email protected]

Options:

• Pneumatic core chuck

• Date coder

• Inkjet printer

• Bag bottom gusset former

• Bag top trimmer

• Handle former

• Speed up kit

• 35″ roll horder

• Core lift chuck for 35″ rolls

• 35″ portable roll stand

• 50Hz electrical

The Model 540E Ice Bagging Machine combines the latest in bag-sealing technology with ultimate versatility in bag sizes and options. With a hot-air top seal, the 540E uses 10% less film than wire-tie machines and supports bag sizes from 5 lbs to 40lbs, all in one convenient package. Offering speeds of 40 bags per minute, the model 540E incorporates the latest automated controls, making bag-size changes fast and easy. Touch screen controls make operator training and machine operation simple. The Model 540E Ice Bagging Machine includes a volumetric feeder for accurate ice dosing.

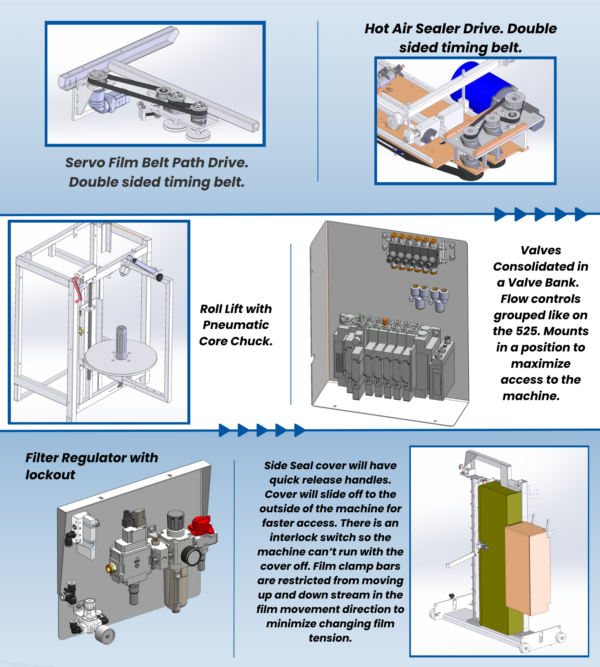

The recent enhancements to the machine include:

- VFD/Servo belt drive film feed that provides greater control and accuracy, as well as lowers maintenance and increases the longevity of components

- Improved side seal access and bag stripper bar adjustments that reduce the frequency and complexity of regular adjustments to the side seal

- Consolidation of pneumatics and wiring to common locations with clearly labeled terminal blocks that simplifies troubleshooting and enhances machine reliability for greater uptime

- Larger HMI screen with native Spanish language support and HMI-controlled top seal heaters

- The optional pneumatic core chuck allows for better film position control from the beginning to the end of the roll

| Dimensions (LxDxH): | 174″L x 35″D x 55″H |

| Electric Requirements: | 460V., 3P., 60Hz |

| Air Requirements: | 1 ea. 30 CFM @ 80 PSI |

| Speed: | up to 40 bags/minute |

| Capacity: | bag sizes 11″ to 18″ and 20″ wide, 14″ to 35″ length |

| Poly thicknesses: | 1.75 mil minimum |

Features:

- Labor savings and increased productivity typically equal to one year investment payback.

- Bag cost savings of up to 20% and less storage space with pre-printed, center-fold poly film compared to remade, open-mouth bags.

- Corrosion-resistant, 304 stainless steel, heavy-duty construction for easy cleaning and servicing.

- Field-proven belt path, bag-to-sealer, and jaw designs reduce the number of moving parts, reducing the need for operator adjustment.

- Designed for fast changeover to accommodate multiple bag sizes.

- AC variable speed controlled volumetric feeder and AC variable speed controlled heat sealer make matching conveyor speeds fast and easy.

- Automatic bag venting

- Easy view low product level light

- Industrial sealed operator switches

- Simplified lever-style jaw assembly

- Serpentine belt path eliminates pulley adjustment

- Extruded film belts improve reliability

- Monochrome touch screen operator control

- 24V DC single control panel

- Hand-held remote control

Hamer Model 5525X Form Fill & Seal (FFS) Packaged Ice Machine

CONTACT A SALES REPRESENTATIVE

phone: (800) 325-3667

email: [email protected]

Options:

• HAMER (model 125-3) 16-gauge wire tie bag closer

• HAMER (model 125-4) 17/18-gauge wire tie bag closer

• Gusset former

• Single-hole punch

• Integrated machine mounted 35” roll holder

• Core lift chuck for 35” rolls

• Pneumatic core chuck

• Inkjet date coder for automatic imprinting of date/shift code on bags

• Embossing coder – 4 or 8 character

• Caster kit

• 3 lb bag

The first model on this platform, the HAMER Brand Model 5525X ice bagging machine, has been completely re-engineered from the ground up, incorporating proven technologies to deliver superior performance and flexibility. This high-speed, automated system efficiently packages ice in bag sizes from 5 to 25 lbs. on a single machine. For precise, high-speed dosing, the 5525X includes an optional servo-driven volumetric filler, easily adjustable via the HMI, along with a reliable wire tie closure for secure bag sealing.

| Dimensions (LxDxH): | 123”L x 41”D x 84”H |

| Electric Requirements: | 230V, 3ph, 60 Hz, 29 FLA |

| Speed: | up to 55 bags/minute |

| Capacity: | Bag Sizes 9” to 16” wide, 16” to 35” long |

| Poly thicknesses: | 1.5 mil minimum |

Features:

- Powered Pinch Roll Film Unwind

- Constant Tension Film Dancer Arm

- Servo-driven film path

- Cut-and-clamp side seal provides an enhanced seal on every bag.

- Easier to align and maintain

- Stainless steel and/or “lube for life” bearings

- Adjustable belt speeds from the HMI

- Self-tracking modular plastic belt conveyor

- Bag cost savings of up to 20% and less storage space with pre-printed, center-fold poly film compared to pre-made open-mouth bags

- Corrosion-resistant, stainless steel, heavy-duty construction for ease of cleaning and long-lasting, trouble-free service

- Horizontal, compact design accommodates system location in low-overhead areas under existing equipment

- Design minimizes product spills and eliminates wasted bags

- Integrated machine-mounted 20” Roll Holder

- Crank adjustment conveyor easily accommodates different bag sizes

- Allen‑Bradley® CompactLogix PLC

- PLC with intuitive HMI controls systems and operations, assuring reliability and consistent performance

- Easily switch the HMI menu language between English and Spanish

- 10 built-in bag recipes for quick setup and changeover

JMC Horizontal Form-Fill & Seal Bagger

CONTACT A SALES REPRESENTATIVE

phone: (800) 325-3667

email: [email protected]

Options:

• Gusset Former

• Inkjet Printer Package

• Scrap trim or tear-off

• Mobility Kit

- Fully automated control of the bagger, upstream feed, and downstream bag transition to the JMC master baler or JMC Robot Palletizer.

- Quick product changeover with easily accessible, maintenance-friendly heat-seal tooling.

- A robust, modern PLC control system with remote troubleshooting capabilities.

- Recording of production data.

| Electric Requirements: | 230V, 3ph, 60 Hz 2112i @ 30A 3118i @ 40A |

| Air: | 15cfm @ 90 PSIg clean & dry |

| Capacity: | 2112i model (typically 5-10lb bags) 3118i model (typically 5-40lb bags) |

| Machine Weight: | 2112i @ 2,100lbs 3118i @ 2,700lbs |

Features:

- Omron PLC with standard 10” touch screen operator interface

- Full Stainless Steel and FDA-approved materials/contact surfaces. Improved hygienic design for food safety and easy cleaning

- Servo-controlled axes for repeatable and efficient high-performance motion

- Servo-powered side heat seal assembly (no burning, no fumes)

- Servo-powered top heat seal assembly. Designed to handle wet and cold environments

- Machine indexes product bags from std registration marks or from clear film with no markings based on the desired bag width

- Optional cup-style rotary volumetric filler for higher throughput and better accuracy. Conventional drum volumetric is available for height-restricted applications

- Vibrating infeed chutes to improve product flow

- Pneumatic core chuck for positive gripping of the film roll

- Adjustable bag top release for consistent product discharge onto downstream equipment

JMC Bulk Ice Bagger

CONTACT A SALES REPRESENTATIVE

phone: (800) 325-3667

email: [email protected]

Options:

• JMC FuseAire 4 Hot Air Sealer

• JMC Bag Kicker with longer T.A.C. to accommodate palletizer

• Spare Parts Kit

• Mobility Kit

• Epoxy powder baked finish

- Saves on manual labour

- Fully automatic

- Fast bag changeover

- Proven technology and reliable performance

- Customized to suit applications

- Machine sets bagging pace

- Fast payback

| Electric Requirements: | 230/460/550 volt, 3ph, 60 Hz (min. 208 V) |

| Air: | 4 CFM @ 80 PSI |

| Capacity: | Adjustable up to 10lb maximum per dump |

| Machine Weight: | Approx. 1200 lbs. |

Features:

- P.L.C. (programmable logic controller)

- Adjustable conveyor height

- Adjustable bag wicket

- Bag inflation system

- Bale pusher with bag transport gripper

- Take-away conveyor

- Stainless steel panel and contact parts

- Integral electrical control panel

- Bagging speed selectable on touchscreen

- Bag sense: “No bag, no dump.”

- Volumetric feeder

- Stainless steel finish