If you are considering adding ice-making equipment with an expected daily production of 10 tons or less, it is important to weigh both the advantages and disadvantages when choosing between air-cooled or water-cooled machines.

PROS FOR AIR-COOLED

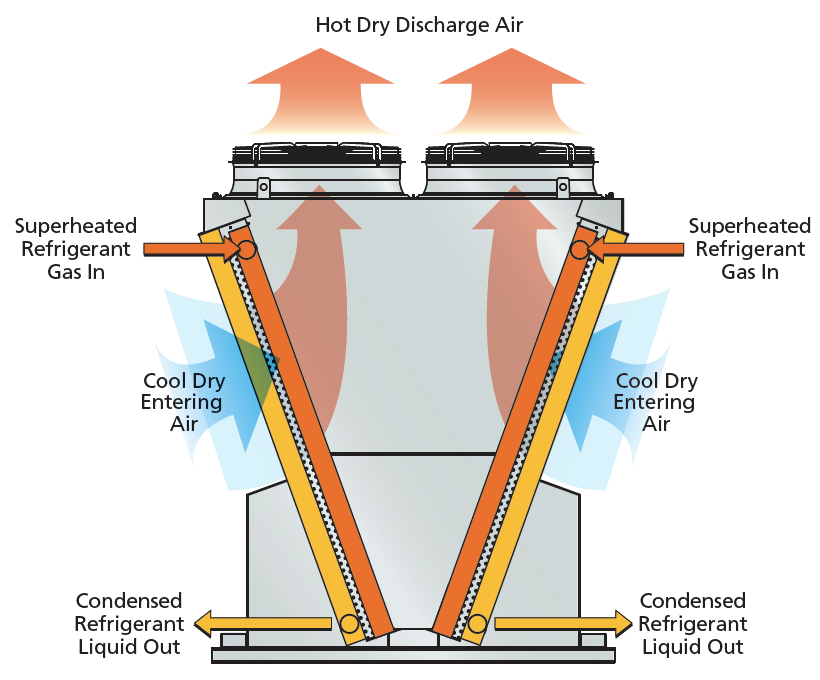

- Air-cooled condensers do not use any water or require any water piping

- There is no potential for freezing up, no pumps to deal with, less maintenance

- Great for locations with high water costs or high TDS/hard water

- Air-cooled Vogt® Ice machines are slightly cheaper than water-cooled machines

CONS FOR AIR-COOLED

- Larger footprint

- More fan horsepower vs. water-cooled

- High ambient temperatures can negatively impact performance

- Higher energy consumption as air is less efficient than water for heat transfer

- The air-cooled condenser must be installed at an elevation above the ice maker

- An air-cooled condenser is more expensive than a cooling tower

PROS FOR WATER-COOLED

- Water-cooled uses a cooling tower, which has a smaller footprint than an air-cooled condenser

- Cooling towers generally cost less than an air-cooled condenser

- More efficient than air-cooled, less fan horsepower

CONS FOR WATER-COOLED

- Water usage

- Risk of freeze-up when operating in below-freezing conditions

- More maintenance, scale buildup in the cooling tower and condenser that must be cleaned on a regular schedule

If your company is considering growing its ice production platform, AIS can help you make the best purchasing decisions to better meet your needs today and as your company grows into the future.